Junk Drawer

-

4/24/2024

Naquan Rollings' "Roadkill" Ep.3

Homing in on the heart of Manhattan, a heavy crew of big names and local legends unlock new potential on the well-trodden blocks. From Tyson’s opening underground hit to Felipe’s final punch at the Pyramid Ledges, Naquan captures the pulse of his hometown. -

4/24/2024

"Roadkill Ep. 3" Premiere Photos

Middle fingers, peace signs and all sorts of PDA were seen in spades at the Roadkill premiere. See the right way to celebrate your favorite street production. -

4/24/2024

Timber “Ice Baths” Video

From Seoul to Bangkok and back again, Jason, Hojin, and Eugene Choi shred savory terrain for Timber. -

4/24/2024

Tylor Horton for LRG x MAXALLURE

Huge snaps and a heavy repertoire, Tylor puts it down for LRG and Maxallure. -

4/24/2024

Unknown Boardshop's "Salish Return" Video

Up in Bellingham, Washington, Cam Barrett and Josh Knapp dig into the local crust in their killer shared part for Unknown Boardshop. -

4/23/2024

Skateline 04.23.2024

Gary gets into Asics' Next Vibrant Screentest video, Miles Silvas' SOTY Trip video, Andrew Reynolds for Spitfire, Lil Dre for adidas, Alex Midler, Martino Cattaneo, Mike Man and more in today's episode of Skateline. -

4/23/2024

New from Deluxe: Easy Riders

After some extensive R-and-D with Ben Degros, the people at Deluxe got a new shape ready to roll. Check the specs here. -

4/23/2024

Todd Francis' "Pigeon Droppings" Art Show at DLX

Todd Francis teamed up with Stance to bring a selection of his iconic pigeons to the walls of DLX on Market. Get there Saturday. -

4/23/2024

"The Central Park Flatground Club" Trailer

In his follow up to The Upper West Side Curb Club, Greg Navarro embeds with a huge cast to cover New York's most famous park. Get a peak at the project here. -

4/22/2024

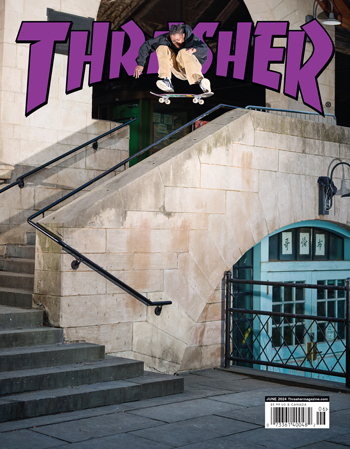

Miles Silvas SOTY Trip - Mexico City

The SOTY victory lap scorched through CDMX, backed by heavyweights like Ishod, Tiago, P-Rod and Shanahan. Clips were stacked, vibes were high and Miles stomped a beautiful back noseblunt for the cover. Hasta pronto, México! Thanks, Skullcandy, for all the help with the trip.

-

4/25/2024

"Roadkill Ep. 3" Premiere Photos

Middle fingers, peace signs and all sorts of PDA were seen in spades at the Roadkill premiere. See the right way to celebrate your favorite street production. -

4/25/2024

Deedz for ACE Limited

Dodging traffic and plowing through the worst ground imaginable, Deedz connects deadly ledges and rails in an unforgettable all-terrain performance. -

4/25/2024

Skateline: 04.16.2024

Gary chops up Deedz for Ace Limited, Kieran Woolley's Raw Ams Indy part, Zach Saraceno's King part, Vincent Alvarez' Suds part, Tyler Surrey, Mike Arnold, Jordan Thackery and more in today's episode of Skateline. -

4/25/2024

MASHER: Estonia

Gregson and company bounce over to the Baltics on their endless quest for killer ‘crete and encounter a trove of sick spots, including a skateable boat and some perfect plazas. Jaws and Nolan Miskell join the crew for added impact. -

4/25/2024

Rough Cut: Louie Lopez' "As You Wish" Cons Part

Lou's smooth style may give the impression that he’s on cruise control, but this feature-length peak behind the curtain showcases the depth of his dedication. Tap in as he ducks security and snags the cover in his iconic Cons part. -

4/25/2024

Skateline: 04.09.2024

Gary dives into Nile Gibbs' GX1000 part, Girl's GRL-NYC-GMV video, SK8Mafia's Micro Dos video, Tanner Burzinski's WKND part, Austin Heilman, Gunner Beck and more in today's episode of Skateline. -

4/25/2024

Guy Mariano's Dickies Release Party Photos

Guy got his own signature Dickies line and it just happened to drop on his birthday. See some of the heaviest of all time come by to give him his flowers. -

4/25/2024

Create and Destroy: John Worthington

Taking inspiration from Epic Spots, John Worthington's approach to glass-blowing borders on the surreal. Stare into the fire as he brings his China Banks bong to life. -

4/25/2024

Turkey Neck Zine's "Surface Nuisance" Video

Elijah, Gus, Tony and a massive cast of madmen capture an absurd level of conflict and chaos from The Bay to Burnside. Turkey Neck literally fires it up. -

4/25/2024

Skateline: 04.02.2024

Gary gives the rundown on Toby Ryan's REAL part, 510's Anywhere's Fine video, Chris Moore, Guy Mariano, a strange new game show and more in today's episode of Skateline.

Departments

Events

In The Mag

Kader finally gives us an excuse to put on him on the front—booming switch frontside flip from Chinatown straight to your eyeballs. More for your eyeballs in this issue include, but definitely not limited to: Jereme Knibbs, Braden Hoban, Frankie Spears, Vans in Australia. Get yours today.